The manufacturing landscape is constantly evolving, driven by technological advancements, shifting consumer demands, and a growing emphasis on sustainability. To thrive in this dynamic environment, manufacturers need robust ERP systems that can adapt to new challenges and opportunities. This guide explores the latest trends in ERP technology and highlights the best ERP systems equipped to empower manufacturers in the years to come.

Toc

- 1. Introduction to ERP for Manufacturers

- 2. Key Features to Consider in the Best ERP Systems for Manufacturing

- 3. The Evolving Landscape of Manufacturing ERP

- 4. Related articles 01:

- 5. Top ERP Systems for Manufacturing

- 6. Related articles 02:

- 7. Implementation and Integration of Your ERP System

- 8. Conclusion

Introduction to ERP for Manufacturers

Enterprise resource planning (ERP) systems have long been the backbone of many manufacturing operations, providing a centralized platform for managing and analyzing various business processes. However, with the rapid pace of technological innovation and changing market conditions, traditional ERP systems may struggle to keep up with the evolving needs of modern manufacturers.

In recent years, we have seen a significant shift towards more flexible and agile ERP solutions that can support manufacturers in adapting to new challenges and seizing opportunities. This guide aims to provide an overview of these trends and highlight the best ERP systems available for manufacturers today.

What is ERP for Manufacturing?

Enterprise Resource Planning (ERP) systems serve as a central hub for managing various aspects of a manufacturing business. From production and inventory to finance and human resources, the best ERP systems enable manufacturers to streamline operations and make data-driven decisions.

Benefits of ERP Systems in Manufacturing

Implementing the best ERP software can lead to several advantages, including:

- Increased Visibility: Gain real-time insights into operations, allowing for better decision-making. For example, a manufacturer can track the progress of a specific production order in real-time, identifying potential bottlenecks and taking corrective actions. This allows them to make informed decisions about resource allocation, production scheduling, and inventory management, leading to increased efficiency and reduced downtime.

- Improved Inventory Management: Optimize stock levels and reduce costs associated with excess inventory. ERP systems provide sophisticated inventory management tools like Material Requirements Planning (MRP) and Advanced Planning and Optimization (APO), which help manufacturers forecast demand, plan production schedules, and optimize inventory levels. This ensures that they have the right materials on hand at the right time, minimizing stockouts and excess inventory, leading to cost savings and improved cash flow.

- Enhanced Production Planning: Streamline scheduling and resource allocation to meet deadlines effectively. ERP systems enable manufacturers to create detailed production schedules, allocate resources effectively, and track production progress in real-time. This allows for dynamic adjustments to schedules based on changing demand or production constraints, ensuring timely delivery of products and maximizing overall efficiency.

- Streamlined Financial Processes: Automate financial reporting and budgeting for better financial control.

- Better Customer Service: Improve responsiveness to customer inquiries and orders.

- Compliance and Quality Control: Ensure adherence to industry regulations and maintain product quality. ERP systems provide tools for managing compliance standards and tracking quality metrics, enabling manufacturers to identify potential issues and take corrective actions before they impact production.

Trends Shaping ERP for Manufacturing

The following are the key trends shaping the future of ERP in manufacturing:

- Cloud Computing: The adoption of cloud-based ERP solutions is on the rise, offering greater flexibility, scalability, and cost savings compared to traditional on-premise systems. Cloud ERP also allows for easier integration with other business applications and enables remote access, making it ideal for today’s distributed workforce.

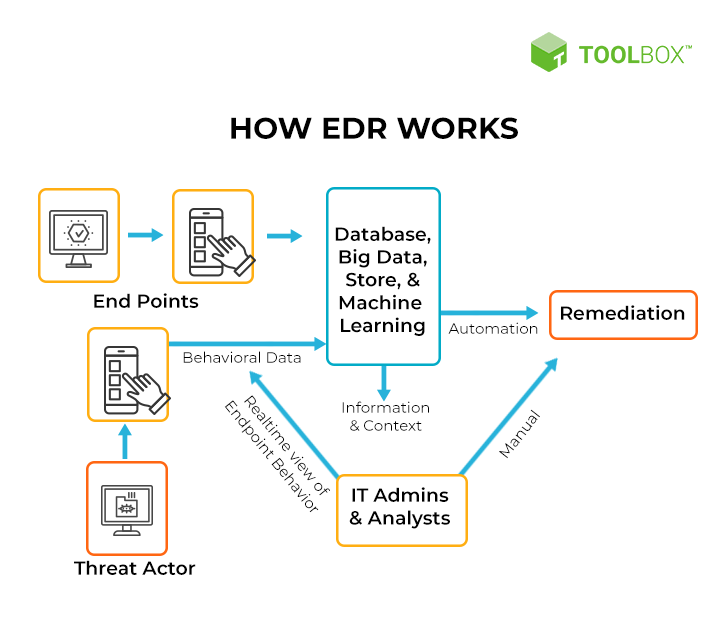

- Internet of Things (IoT): IoT devices are increasingly being used in manufacturing facilities to capture real-time data on machines, processes, and products. This data can be integrated into ERP systems, providing manufacturers with valuable insights into operations and enabling predictive maintenance to reduce downtime.

- Big Data and Analytics: With the proliferation of IoT devices and other sources of data, manufacturers are generating large volumes of information that can be leveraged for better decision-making. ERP systems are equipped with advanced analytics capabilities, allowing manufacturers to make sense of this data and gain deeper insights into their operations.

- Artificial Intelligence (AI): AI is being integrated into ERP systems to automate routine tasks, enhance forecasting accuracy, and improve decision-making. For example, AI-powered production scheduling algorithms can quickly adapt to changing conditions on the factory floor, ensuring maximum efficiency.

- Mobile Accessibility: With the rise of remote work and the use of mobile devices in the workplace, ERP systems are increasingly being designed with mobile accessibility in mind. This allows for easy access to real-time information and enables employees to perform tasks on-the-go.

Key Features to Consider in the Best ERP Systems for Manufacturing

When evaluating the best ERP systems for manufacturing, several key features should be prioritized:

Production Planning and Scheduling

Effective production planning and scheduling are crucial for optimizing manufacturing processes. Look for ERP systems that offer:

- Material Requirements Planning (MRP): For accurate material ordering.

- Shop Floor Control: To track production progress in real-time.

- Capacity Planning: To optimize resource allocation and maximize productivity.

- Job Costing: For accurate tracking of production expenses.

Inventory Management

Strong inventory management capabilities are essential in any manufacturing ERP solution. Key features include:

- Real-Time Inventory Tracking: To maintain accurate stock levels.

- Warehouse Management: For efficient storage and retrieval of materials.

- Lot Tracking: To manage product batches and expiration dates.

- Demand Forecasting: To plan inventory needs accurately.

Supply Chain Management

A robust supply chain management module is vital. Key aspects to consider are:

- Supplier Management: To maintain healthy vendor relationships.

- Purchase Order Management: For efficient procurement processes.

- Transportation and Logistics Management: To optimize delivery operations.

- Supplier Quality Management: To ensure consistent product quality.

Quality Management

Quality management features are essential for manufacturers focused on delivering high-quality products. Important functionalities include:

- Quality Control Processes: To monitor product quality at different stages.

- Non-Conformance Management: To track and address quality issues.

- Statistical Process Control (SPC): For monitoring production processes statistically.

- Quality Audits: To maintain compliance and drive continuous improvement.

Financial Management

Integrated financial management capabilities are a must-have in the best ERP systems. Look for features such as:

- General Ledger Accounting: For accurate financial reporting.

- Accounts Payable and Receivable: To manage financial transactions efficiently.

- Budgeting and Forecasting: For effective financial planning.

- Cost Accounting: To track production costs accurately.

The Evolving Landscape of Manufacturing ERP

1. https://cacaocafenewjersey.com/archive/328/

2. https://cacaocafenewjersey.com/archive/324/

3. https://cacaocafenewjersey.com/archive/342/

The manufacturing sector is constantly evolving, and so are the ERP solutions designed for it. As new technologies emerge, manufacturers need to stay updated with the latest trends and advancements in ERP systems to remain competitive. Some of the key developments shaping the future of manufacturing ERP include:

- Industry 4.0: This concept encompasses advanced automation, data exchange, and smart factories that leverage technologies such as IoT, AI, and cloud computing. As manufacturers embrace Industry 4.0, ERP systems will become more advanced, incorporating these technologies to drive greater efficiency and productivity.

- Blockchain: The use of blockchain technology in supply chain management is gaining traction in the manufacturing industry. By integrating blockchain into ERP systems, manufacturers can achieve enhanced traceability and transparency in their supply chains, reducing the risks of counterfeiting and fraud.

- Robotics: With the rise of collaborative robots or “cobots,” which work alongside human workers, there is a growing need for ERP systems to integrate with robotics on the factory floor. This integration can streamline processes and improve overall production efficiency.

AI and Machine Learning in Manufacturing ERP

AI and machine learning are rapidly transforming manufacturing ERP systems. These technologies can analyze vast amounts of data to predict demand, optimize production schedules, identify potential equipment failures, and improve quality control. For example, AI-powered predictive maintenance can identify potential equipment failures before they occur, reducing downtime and maintenance costs. This is a game-changer for manufacturers seeking to enhance operational efficiency and minimize disruptions.

Cloud-Based ERP for Manufacturing

Cloud-based ERP solutions are gaining traction in the manufacturing sector due to their scalability, affordability, and accessibility. Cloud-based systems allow manufacturers to access their data and applications from anywhere with an internet connection, eliminating the need for expensive hardware and software installations. This also enables easy integration with other business systems and promotes collaboration across different departments.

Top ERP Systems for Manufacturing

Here’s a detailed overview of some of the best ERP systems available for manufacturers in 2024:

NetSuite ERP

NetSuite ERP is a leading cloud-based solution known for its comprehensive suite of modules. It excels in financial management and offers:

- User-Friendly Interface: Easy navigation for users.

- Robust Reporting and Analytics: For in-depth business insights.

- Extensive Integrations: Seamlessly connects with other software.

While it provides scalability, it can be costly and may require significant customization for complex manufacturing processes.

SAP Business One

SAP Business One is tailored for small and medium-sized enterprises, offering a blend of comprehensive functionality and affordability. Key features include:

- Customization Options: Allows businesses to adapt the system to their needs.

- Industry-Specific Solutions: Designed for various manufacturing sectors.

However, it may not scale well for larger enterprises and often requires additional modules for complex needs.

Epicor Prophet 21

Epicor Prophet 21 specializes in distribution but also offers robust inventory and supply chain management features. Highlights include:

- Integration with B2B E-commerce Platforms: Enhances distribution processes.

- Real-Time Insights: Improves inventory management.

Its limitations lie in functionality for complex manufacturing processes, making it less suitable for all manufacturers.

Acumatica Cloud ERP

Acumatica Cloud ERP is a highly customizable solution ideal for manufacturers seeking flexibility. Notable features include:

- User-Friendly Interface: Simplifies user experience.

- Affordable Pricing: Offers good value for small to medium businesses.

Despite its strengths, it may have limited third-party integrations and require additional modules for complex needs.

Microsoft Dynamics 365

Microsoft Dynamics 365 offers a comprehensive suite of modules with strong customer relationship management capabilities. Key benefits include:

- Integration with Microsoft Products: Streamlines workflows for users familiar with Microsoft software.

- Customization Options: Tailorable to specific manufacturing needs.

On the downside, it can be expensive and may require extensive training for effective use.

Sage Intacct

Sage Intacct is primarily an accounting platform that has evolved into an ERP solution. Key features include:

1. https://cacaocafenewjersey.com/archive/328/

2. https://cacaocafenewjersey.com/archive/324/

3. https://cacaocafenewjersey.com/archive/327/

- Robust Financial Management: Specializes in accounting and financial reporting.

- User-Friendly Interface: Easy to navigate and use.

However, it lacks manufacturing-specific features, which may necessitate additional modules for some businesses.

Genius ERP

Genius ERP is tailored for custom manufacturers, addressing unique production needs. Key aspects include:

- Integration with CAD Software: Facilitates design and production processes.

- High-Variable and Multi-Stage Production Management: Optimizes complex manufacturing operations.

Its scalability may be limited for larger enterprises, and it might not fit all manufacturing scenarios.

Syspro

Syspro provides both on-premise and cloud-based options with strong inventory and supply chain management capabilities. Notable features include:

- User-Friendly Interface: Simplifies user experience across departments.

- Scalability: Adapts to the growth of the business.

However, it may have restricted third-party integrations and could be costly for smaller firms.

JD Edwards EnterpriseOne

JD Edwards EnterpriseOne is a robust ERP system offering a comprehensive suite of modules. Key features include:

- Strong Asset Lifecycle Management: Supports various manufacturing processes.

- Scalability: Suitable for both small and large enterprises.

On the downside, it can be complex to implement and may require significant training and investment.

Implementation and Integration of Your ERP System

Implementing an ERP system is a major investment, requiring careful planning and execution to ensure a successful rollout. Consider the following for a successful implementation:

Develop a Comprehensive Implementation Plan

A comprehensive implementation plan is crucial to navigate the complexities of deploying an ERP system. Begin by defining clear objectives and goals, aligning them with your organization’s strategic vision. Assemble a skilled project team that includes cross-functional experts, IT specialists, and end-users to ensure diverse perspectives and expertise. It’s essential to conduct a thorough business process analysis to identify existing workflows and potential areas for improvement. Furthermore, establish a realistic timeline and budget, taking into account potential setbacks and resource constraints.

Training and Support

Effective training and support structures are paramount to a successful ERP implementation. Invest in comprehensive training programs tailored to different user roles, ensuring all employees are comfortable navigating the new system. Continuous support post-implementation can help address emerging challenges and foster user confidence. Consider establishing a helpdesk or utilizing external consultants for additional support during the transition.

Data Migration and Testing

A critical phase in ERP implementation is data migration and testing. Ensure data is accurately transferred from legacy systems to the new ERP, verifying data integrity and completeness. Rigorous testing procedures will help identify and address any technical issues before the system goes live. Engaging end-users in testing can also provide valuable feedback to refine the system configuration and user interface.

Evaluating Success and Continuous Improvement

Post-implementation, it’s important to evaluate the system’s performance against the set objectives. Gather feedback from users and stakeholders to identify areas for further improvement. ERP systems evolve over time, so regular updates and enhancements should be part of a long-term strategy to maintain alignment with business goals and technological advancements. Continuous improvement can maximize the value derived from an ERP investment, keeping the organization agile and competitive in an ever-changing market.

Conclusion

In conclusion, selecting the right ERP system and ensuring its successful implementation are pivotal steps for any manufacturing organization aiming to enhance its operational efficiency and competitiveness. With a plethora of options available, from tailored solutions like Genius ERP to comprehensive suites like JD Edwards EnterpriseOne, businesses must assess their specific needs, budget, and growth plans. By focusing on strategic planning, thorough training, accurate data migration, and continuous evaluation, companies can navigate potential challenges and leverage their ERP system to drive meaningful improvement. As technology continues to evolve, maintaining an adaptable approach will be key in harnessing the full potential of ERP systems, enabling organizations to thrive in today’s dynamic business environment.